The technology used in CCUS is not new—in fact, it dates back to the 1970s, when CO2 injection was first used as a method of enhanced oil recovery (EOR). Before we dive deeper into the technology, let’s learn about the history of this innovative process.

Primary and Secondary Recovery Methods

The primary process by which oil is produced from underground reservoirs is simply the natural pressure of the reservoir itself. Drilling a well into the oil-carrying formation creates a path to lower pressure and the hydrocarbons naturally move towards the surface to achieve equilibrium. For decades this was the only way humans were able to extract oil from the ground. But we now know that this method is only able to produce about 15% of the original oil in place (OOIP), a measure of the total oil contained in a reservoir.

As more oil is produced, the formation pressure decreases and the natural rise of the oil slows. In order to gain access to a larger percentage of oil reserves, producers developed secondary recovery techniques like water-flooding, whereby water is injected at high enough pressure to physically displace the oil in the direction of a second extraction well and also to maintain reservoir pressure. While this extends the lifecycle of a field significantly, it still can only produce about 20-40% of OOIP.1Bradley, Tim. (n.d.). The CO2 enhanced oil recovery story. Retrieved 10/28/2020 from https://www.edf.org/sites/default/files/10254_Bradley.pdf2U.S. Office of Fossil Energy. (n.d.). Enhanced oil recovery. Retrieved 10/28/2020 from https://www.energy.gov/fe/science-innovation/oil-gas-research/enhanced-oil-recovery Extracting the remaining oil involves more advanced technology and more cost. As a result, reservoirs were historically abandoned at this point.

History: SACROC Field in the Permian Basin

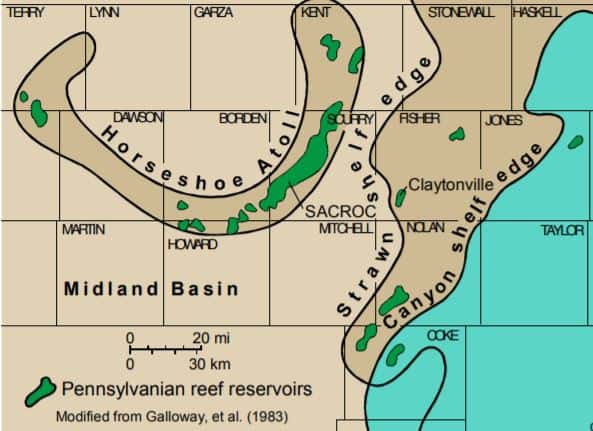

CO2-EOR has been a successful commercial activity in the United States since 1972, when the technology was first applied in the Permian Basin, more specifically in SACROC Field, Texas. The Permian Basin, by far the most active CO2-EOR region in the world, is located in West Texas and southeastern New Mexico. In 1949, William A. “Monty” Moncrief (Moncrief Oil) decided to drill in Scurry County, Texas and offered his golfing friends, Hollywood stars Bob Hope and Bing Crosby, a chance to partner with him. They jumped in. After one dry hole, Moncrief Oil drilled 28 straight successful wells, which turned into the billion-barrel SACROC (Scurry Area Canyon Reef Operators) field.2Permian Basin Petroleum Museum. (n.d.). Wm. A. “Tex” Moncrief, Jr. 1999. Retrieved 10/28/2020 from http://petroleummuseum.org/wp-content/uploads/2013/06/MoncriefTex.pdf

Hollywood stars Bob Hope and Bing Crosby were partners in SACROC.

The field underwent secondary recovery starting in 1954, after reservoir pressure dropped below feasible levels for primary recovery. By the late 60s the amount of daily water injection required to maintain production levels began to grow precipitously. The well-owners made a study of possible options for additional recovery methods and decided that CO2 injection was the most economically feasible. A contributing factor to this decision was the presence of several CO2 stripping plants at a gas well 200 miles south of the field. In 1969 the Texas Railroad Commission approved the CO2 injection plan and the project began in 1972. Since then, over 175 Mt of CO2 have been injected into the SACROC field. About half of that has remained trapped in the subsurface, while the rest is recaptured and recycled at the surface.

The SACROC oil field unit, the main part of the Kelly-Snyder field, lies along a trend of fields described as the Horseshoe Atoll Play. Hydrocarbons are produced from Pennsylvanian-age strata, including the Cisco and Canyon formations, which represent an isolated platform carbonate environment.

As the first ever large-scale CO2-injection project, the SACROC operation had to develop new technology to ensure the safe transport of CO2 to the well-site, building materials to withstand the unique physical and chemical properties of CO2, and best practices for injection to maximize oil production. Many of these advancements are still in use today in the field of CO2-EOR and CCUS in general. And because the SACROC project is the longest running CO2-EOR operation in the Permian Basin, it has served as an ideal natural laboratory to study the long-term effects of subsurface CO2 storage.3Bureau of Economic Geology. (n.d.). SACROC Research Project. Retrieved 10/28/2020 from https://www.beg.utexas.edu/gccc/research/sacroc4Crameik, T. D., & Plassey, J. A. (1972, January). Carbon Dioxide Injection Project Sacroc Unit, Scurry County, Texas. In Annual Meeting Papers, Division of Production. American Petroleum Institute.

History: The Wasson Field in the Permian Basin

Another prominent historic example of CO2-EOR is the Denver Unit of the Wasson Field in the Permian Basin. Occidental Petroleum started operations in the field in 1938. Production peaked in the mid-1940s, so the operator began pressure maintenance with secondary recovery (water flooding) in 1965. CO2-EOR began in 1983, with oil production increasing and stabilizing a few years later.

The Permian Basin, the third largest oil producing region in the United States, has produced over 30 billion barrels of oil, out of which 1.3 billion have been produced with CO2.5Merchant, D. (2017, August). Enhanced Oil Recovery–the History of CO 2 Conventional Wag Injection Techniques Developed from Lab in the 1950’s to 2017. In Carbon Management Technology Conference. Carbon Management Technology Conference.

Contemporary Applications

CO2-EOR continues to provide viable enhanced recovery into the present day. The Weyburn-Midale CO2 Monitoring and Storage Project located in Midale, Saskatchewan, Canada, started CO2 injection in October 2000 and continues to produce oil from Weyburn and Midale oil fields at a rate of 14,000 BOPD (barrels of oil per day). The CO2 injected is captured at a lignite-fired synfuels plant in Beulah, North Dakota, U.S., and transported to the fields via a 330-km long transnational pipeline.6University of North Dakota Energy & Environmental Research Center. (n.d.). Weyburn–Midale CO2 Project. Retrieved 11/3/2020 from https://undeerc.org/pcor/co2sequestrationprojects/Weyburn.aspx

More recently, a couple of large-scale CCUS projects emerged in the United States. The Air Products Capture Project injects CO2 captured at the hydrogen production facility at the Valero Port Arthur Refinery in Texas into the West Hastings field for EOR.7Preston, C. (2018, October 26, revised 2020, October 27). The carbon capture project at Air Products’ Port Arthur Hydrogen Production Facility. 14th Greenhouse Gas Control Technologies Conference Melbourne 21-26 October 2018 (GHGT-14). And the Petra Nova project, currently on hold, injected CO2 captured at NRG’s Parish Power Plant, southwest of Houston, into the nearby West Ranch oil field, also for EOR.8Smyth, J. (2020, August 6). Petra Nova carbon capture project stalls with cheap oil. Energy and Policy Institute. Retrieved 11/8/2020 from https://www.energyandpolicy.org/

Emerging Need for CO2 Supply

In 2019, EOR activities in the Permian Basin produced on average 350,000 BOPD. The IEA estimated world CO2-EOR production at 450,000 BOPD in 2019. The CO2, mostly naturally sourced, is transported to oil fields through a network of 4,500 miles of pipelines. The development of this vast CO2-supply infrastructure in the region has resulted from the increasing CO2 demand for EOR. CO2 supply hasn’t always met the demand, restricting EOR production. The latter is starting to force a change in the low-cost natural CO2 supply trend, with forecasts including emerging industrial CO2 capture projects.9Nuñez-López, V., & Moskal, E. (2019). Potential of CO2-EOR for Near-Term Decarbonization. Frontiers in Climate, 1, 5.

Images: “EOR-History-Header” by NETL-DOE