The best way to learn about the rock units making up a petroleum system is to bring samples up to the surface. In a perfect world, operators would collect intact rock samples from every horizon of interest. Unfortunately, the collection of physical samples is expensive and usually targets a few key well intervals.

Often, the limited amount of information that can be obtained during mud logging (discussed in the next section) doesn’t tell operators everything they need to know about a reservoir. Nothing can really be substituted for an intact sample of rock. Intact rock samples are considered to be the gold standard for the measurement of rock attributes because the rock units in question are sitting right in front of the operator. Most often, intact pieces of rock are retrieved as core samples – long cylindrical pieces of rock removed from the borehole.

There are several methods for retrieving rock cores from the wellbore.

Rock Core Sampling Methods

Diamond Coring

Diamond coring is the most traditional method for retrieving cores. During diamond coring, the drill bit is replaced by a long cylinder called a core barrel, which ends with a diamond studded cutting surface around the end of the cylinder. As the tube grinds into the rock, the cylinder slides over it. Bit lubrication and cooling is provided by drilling mud just as it is during normal drilling. The following picture shows a diamond coring bit with a core section inside of it being extracted. The core is from the Bakken formation. Commonly, diamond-cored cores are 4 inches in diameter but can vary in size.

Once the core barrel is full (typically they can hold about ~9 meters [30 feet] of core, drilling stops temporarily. A device called an overshot is lowered through the drill string and latches onto the inner pipe holding the core. Once the core sample is hoisted out of the well and the inner pipe is replaced, diamond core drilling can resume and another section of the reservoir sampled.

Coring While Drilling

Coring while drilling works in much the same way as traditional diamond drilling, with one key difference – the bottom hole assembly is designed to switch from drilling to coring mode without requiring a round trip. This reduces the overall rig time needed for both drilling and coring operations.

Sidewall Coring

Sidewall coring allows drillers to extract small rock samples from the side of the borehole.

Percussive sidewall coring is accomplished with a wireline tool that contains up to 30 “bullets” – hollow metal cylinders that can be shot into the side of the drilled well via remotely detonated black powder charges. The cylinders are designed to shoot into the sidewall and trap a rock sample inside. When the tool is pulled from the hole, the bullets are pulled in by steel cables, allowing the samples to be retrieved.

Rotary sidewall coring allows samples to be retrieved from the side of the drilled well without experiencing the fracturing and alteration to the core samples caused by percussive drilling. The tool consists of a drill lowered into the well by wireline tools. The drill can extract and store multiple samples during one wireline trip.

Although sidewall samples don’t provide a continuous record of a section of the borehole, they can be used to study a particular rock strata or depth in great detail. They are also significantly cheaper to obtain than traditional, full-length cores.

Measuring / Analyzing Cores

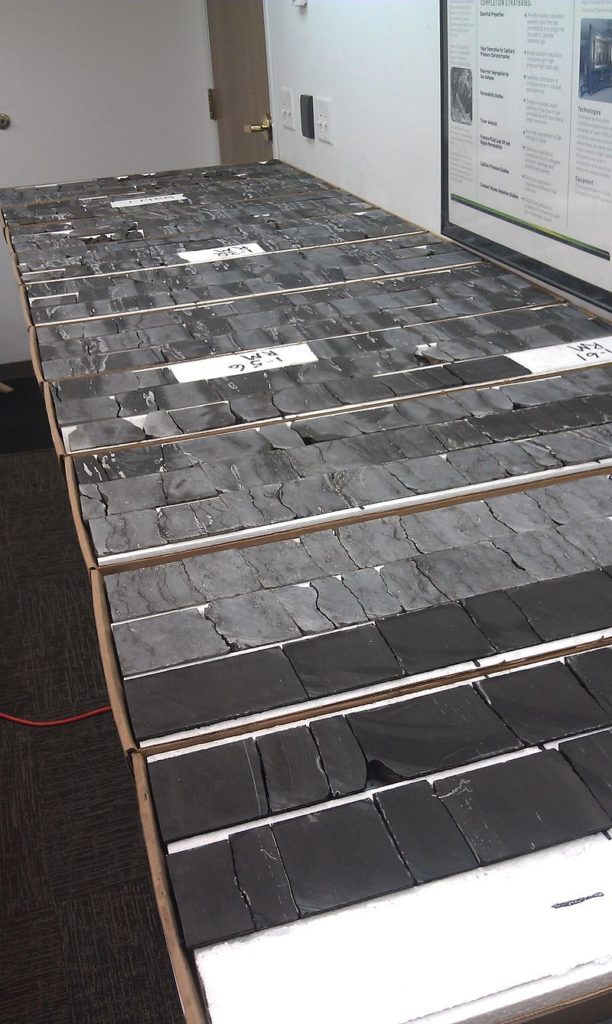

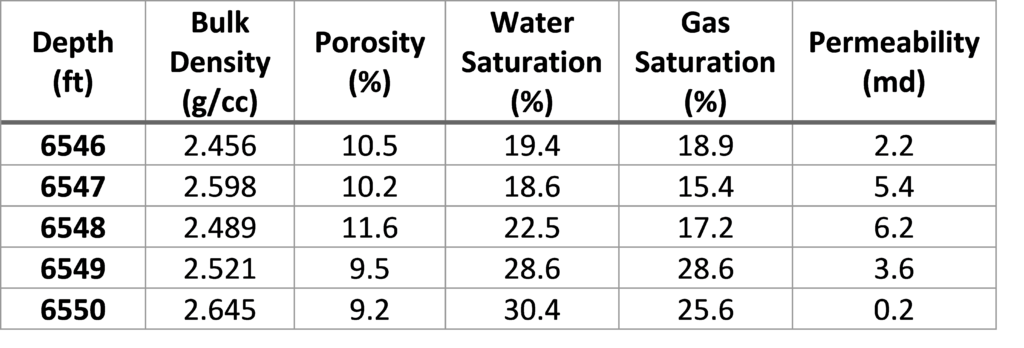

Once a core reaches the surface, it is removed from the core barrel, and may be later split in half vertically and photographed. Additionally, a number of small core plugs, which are a few inches long and about an inch in diameter, may be taken for further lab studies, such as measurements of porosity and permeability.

An example of a typical analysis performed on a core sample is as follows and includes items such as the depth that that core was taken from, the sample density, porosity, permeability, etc. Additional tests can include X-ray diffraction to determine the minerals present, acoustic velocities to determine mechanical properties, gamma ray measurements to determine radioactivity, and photographs under different light spectra.

One simple yet powerful method for analyzing cores containing potential source rocks is known as vitrinite reflectance analysis. This process allows geologists to determine the thermal maturity of a source rock, which allows them to predict whether it is producing or has produced oil, gas, or both.

One of our experts will explain the method in more detail in this video.

Transcript

Vitrinite Reflectance – Steve Sonnenberg – Colorado School of Mines

Geologists have ways of determining the thermal maturity of potential source rocks even if they don’t know the geologic history of the rock. One of these methods is called vitrinite reflectance.

Vitrinite is found in coal and kerogen and it can also be found distributed throughout sedimentary rocks of many kinds.

By looking at how shiny the grains of vitrinite are in a sample of rock from a potential reservoir, we can measure how long the target organic matter has spent under conditions ripe for the development of oil and gas.

Here’s how it’s done.

Starting with a rock sample, we crush it and separate out the kerogen by soaking the rock dust in acid. We put the resultant residue, which will contain some vitrinite particles, on a microscope slide and polish it. We then bounce light off the slide using a reflecting light microscope, and measure how reflective the vitrinite particles in the residue are.

The mathematical term we use for the degree of reflectivity of these particles is Ro. Even though vitrinite is shiny, it is also black, meaning it only reflects a few percentage points of the light landing on it.

The numerical value of Ro is that percentage of reflected light, so they are small numbers. If an object were completely black, it would score an Ro of zero. What we see if the kerogen under examination has been matured enough to create hydrocarbons are values ranging from .6 to about 3.

An expert trained in vitrinite reflectance will produce reflectance readings from numerous slides from the same sample area and plot those values graphically. They’re looking for an average reflectance value for the zone under examination.

What we’ve found is that if the vitrinite reflects approximately .6 to 1.5 of the light, that suggests the formation has undergone conditions necessary to generate crude oil.

If the Ro values are between 1.5 and 3, that suggests the formation produced natural gas. And if the Ro values are higher than three, then all the hydrocarbons have probably been cooked out of the kerogen.

Despite vitrinite reflectance being a fairly low-tech method of determining the maturity of a potential source rock, it’s still accurate and effective, so until we find a way that is cheaper, faster or better, it’s going to remain the most popular method we have to make that determination.

Vitrinite reflectance and other similar methods allow geologists to develop an understanding of the production potential of a formation before deciding whether it is worth investing more time and money to complete the hole.

Images: “Diamond_Core_crop” by Blastcube via Wikimedia Commons licensed under CC BY SA 3.0; “Pulling_the_Bakken_Core” by Joshue Dobek via via Wikimedia Commons; “Geological,Core,Samples,In,Core,Boxes,Ready,For,Analysis” by ribeiroantonio via Shutterstock; “Cut_Bakken_Core_samples” by Joshua Doubek via Wikimedia Commons; “Core analysis graph” by Top Energy Training