Oil and gas production requires a number of facilities and components including oil and gas batteries, well pads, rigs, surface impoundments, access roads, pipelines and treating facilities, oilfield injection and treating facilities, and pump stations or compressor stations. A battery is an upstream facility in an oil or natural gas field that collects raw oil or natural gas from one or more wells. Oil, gas and water are separated at this facility, impurities removed and the purified liquids are piped for further processing or distribution. Water may be piped to an injection well where it is disposed into a geologic formation beneath the earth’s surface.

The configuration depends on the size of the oil field. For simple fields comprising a single well or a few wells an oil storage tank may be sufficient. The tank is emptied periodically by road tanker and transferred to an oil refinery. For larger production rates a rail tanker transfer facility may be appropriate. For larger fields a full three-phase processing facility is required. Three-phase separators separate the well fluids into its three constituent phases: oil, gas and produced water. Oil may be transferred by road or rail tanker or by pipeline to an oil refinery. Gas may be used on the site to run gas engines to produce electricity or can be piped to local users. Excess gas is burned in a ground flare. Produced water may be re-injected into the reservoir.

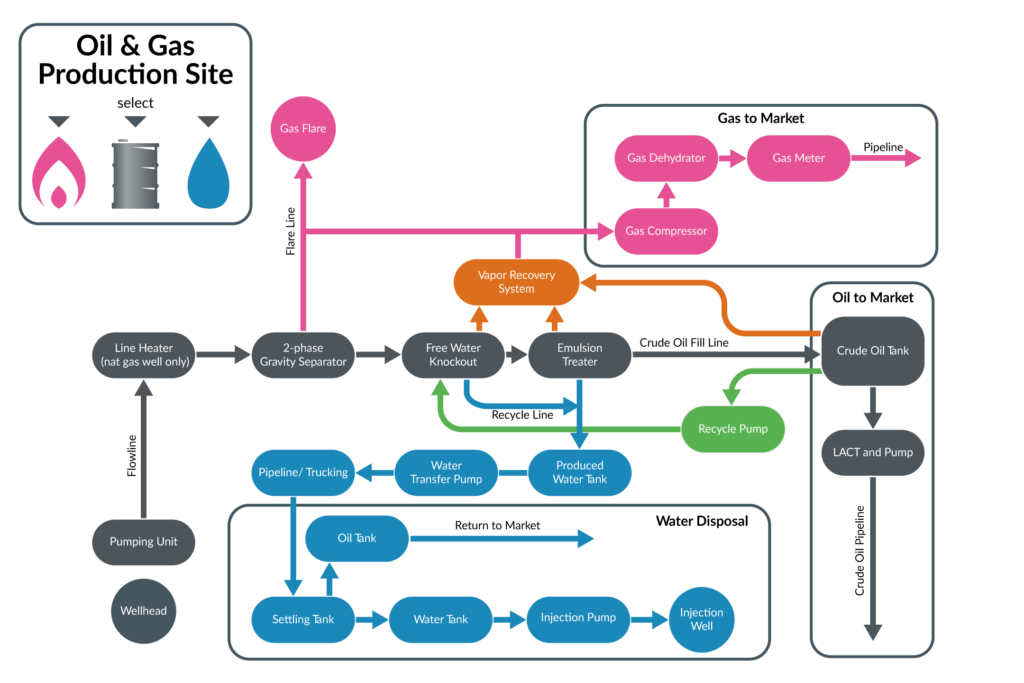

The diagram below shows the typical path of fluids after reaching the surface. You can isolate the path of water, crude oil and natural gas through the different processing and storage equipment at the surface. Although this is a simplified model of a production site, you can see how many connections and colocations can introduce environmental risks. Click the image below to launch the interactive diagram.

One of our experts explains common equipment you might find at a site and how the system works internally and with the larger oil and gas stream as a whole. Click below to launch the virtual tour of the production site.

Images: “Barnett Shale Tanks” by J. Veil, Argonne National Labs; “picture” by Bismark Tribune