Class II wells include all injection wells associated with oil and gas production operations. However, the Underground Injection Control (UIC) program does not include any wells that are used exclusively for production. The number of Class II wells varies from year to year based on fluctuations in oil and gas demand and production. Approximately 180,000 Class II wells are in operation in the United States, comprising ~25% of all UIC wells. Inspections were completed on ~45% of those wells according to the U.S. Environmental Protection Agency (EPA) data below.1USEPA. (2020). Underground Injection Control Program Fact Sheet. EPA 816F19005 April 2020.

Underground Injection Wells by Class

| Injection Well Class | Number of Injection Wells | Injection Wells Inspected |

|---|---|---|

| Class I | 830 | 453 |

| Class II | 181,431 | 84,317 |

| Class III | 28,327 | 406 |

| Class IV | 122 | 27 |

| Class V | 531,176 | 4,038 |

| Class VI | 2 | 0 |

Source: EPA2USEPA. (2020). Underground Injection Control Program Fact Sheet. EPA 816F19005 April 2020.

States (tribes and territories) have the option of requesting primacy for Class II wells under either Section 1422 or Section 1425 of the SDWA.3USEPA. (2022, August 2). Class II oil and gas related injection wells. Retrieved 12/20/20220 from https://www.epa.gov/uic/class-ii-oil-and-gas-related-injection-wells.

Under Section 1422 states must meet EPA’s minimum requirements for UIC programs. Programs authorized under section 1422 must include well owner and operator requirements for:4USEPA. (2022, August 2). Class II oil and gas related injection wells. Retrieved 12/20/20220 from https://www.epa.gov/uic/class-ii-oil-and-gas-related-injection-wells.

- Construction

- Operation

- Monitoring and testing

- Reporting

- Closure requirements

Under Section 1422 enhanced recovery wells may either be issued permits or be authorized by rule. Disposal wells are issued permits. The owners or operators of the wells must meet all applicable requirements, including strict construction and conversion standards and regular testing and inspection.5USEPA. (2022, August 2). Class II oil and gas related injection wells. Retrieved 12/20/20220 from https://www.epa.gov/uic/class-ii-oil-and-gas-related-injection-wells.

Under Section 1425 states must demonstrate that their existing standards are effective in preventing endangerment of USDWs. These programs must include requirements for:6USEPA. (2022, August 2). Class II oil and gas related injection wells. Retrieved 12/20/20220 from https://www.epa.gov/uic/class-ii-oil-and-gas-related-injection-wells.

- Permitting

- Inspections

- Monitoring

- Record-keeping

- Reporting

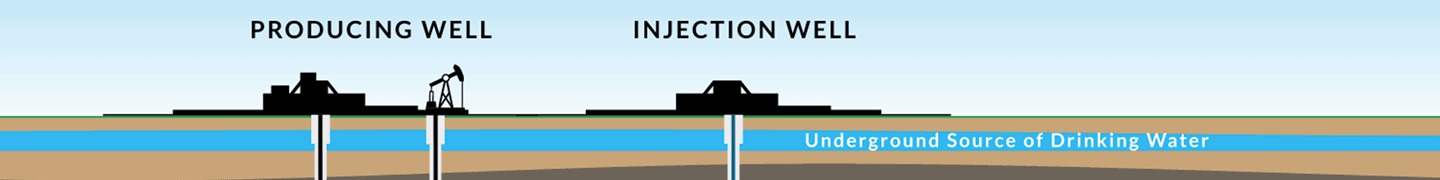

Class II wells are subdivided into three broad subcategories: disposal, enhanced oil recovery, and hydrocarbon storage.

Categories of Class II Wells

Disposal

During oil and gas production, water associated with the producing formation rises to the surface with hydrocarbons. This produced water may be called brine, as it may contain high levels of salts or other dissolved solids. Operators separate produced water from the oil and gas at the surface and return it to subsurface formation for disposal using injection wells. Operators also use Class II injection wells to inject flowback water from hydraulic fracturing. Class II wells may also receive other forms of exploration and production waste such as gas plant waste cooling tower blowdown. Class II disposal wells make up about 20% of the total number of Class II wells.7USEPA. (2022, August 2). Class II oil and gas related injection wells. Retrieved 12/20/20220 from https://www.epa.gov/uic/class-ii-oil-and-gas-related-injection-wells.

Enhanced Oil Recovery

While the EPA does not regulate oil and gas production wells, some enhanced oil recovery techniques inject fluids using wells that fall under these regulations. Operators use enhanced oil recovery techniques in cases of heavy oil, and in some cases tight oil and gas scenarios. Enhanced recovery wells account for approximately 80% of all Class II wells.8USEPA. (2022, August 2). Class II oil and gas related injection wells. Retrieved 12/20/20220 from https://www.epa.gov/uic/class-ii-oil-and-gas-related-injection-wells.

Hydrocarbon Storage

After production liquid hydrocarbons may be stored underground. Over 100 Class II liquid hydrocarbon storage wells operate in the United States.9USEPA. (2022, August 2). Class II oil and gas related injection wells. Retrieved 12/20/20220 from https://www.epa.gov/uic/class-ii-oil-and-gas-related-injection-wells. The United States maintains a massive underground Strategic Petroleum Reserve (SPR) with a total authorized storage capacity of 714 million barrels of crude oil.10Office of Cybersecurity, Energy Security, and Emergency Response. (2022, November 30). SPR Quick Facts. Retrieved 12/30/2022 from https://www.energy.gov/ceser/spr-quick-facts.

Hydraulic Fracturing

The Energy Policy Act of 2005 exempted hydraulic fracturing activities on wells drilled for production operations from the UIC provisions of the SDWA. As a result, injection for hydraulic fracturing is not covered by UIC regulations except in one specific case. If operators plan to stimulate a formation with fracturing fluids that contain any amount of diesel fuel, the well falls under Class II regulations, including the appropriate permitting and program requirements.

Diesel fuel when used as a component of drill mud, pipe joint compounds used in well construction or used in motorized equipment on the surface is not subject to UIC Class II permitting requirements in certain cases.

The EPA has provided UIC Guidance 84 regarding Oil and Gas Hydraulic Fracturing Activities Using Diesel Fuels.11USEPA (2014). Permitting guidance for oil and gas hydraulic fracturing activities using diesel fuels: Underground Injection Control Program Guidance #84.

What is a diesel fuel according to UIC Guidance 84?

A hydraulic fracturing activity is subject to UIC Class II permitting requirements under the SDWA if any portion of the injectate contains “diesel fuels.” The EPA interprets this statutory term to mean any of the following five CASRNs (Chemical Abstracts Service Registry Number):

- CASRNs: 68334-30-5 Primary Name: Fuels, diesel Common Synonyms: Automotive diesel oil; Diesel fuel; Diesel oil (petroleum); Diesel oils; Diesel test fuel; Diesel fuels; Diesel fuel No. 1; Diesel fuel [United Nations-North America (UN/NA) number 1993]; Diesel fuel oil; European Inventory of Existing Commercial Chemical Substances (EINECS) 269-822-7.

- CASRNs: 68476-34-6 Primary Name: Fuels, diesel, No. 2 Common Synonyms: Diesel fuel No. 2; Diesel fuels No. 2; EINECS 270-676-1; No. 2 Diesel fuel.

- CASRNs: 68476-30-2 Primary Name: Fuel oil No. 2 Common Synonyms: Diesel fuel; Gas oil or diesel fuel or heating oil, light [UN1202] No. 2 Home heating oils; API No. 2 fuel oil; EINECS 270-671-4; Fuel oil No. 2; Home heating oil No. 2; No. 2 burner fuel; Distillate fuel oils, light; Fuel No. 2; Fuel oil (No. 10 US EPA,

- CASRNs: 68476-31-3 Primary Name: Fuel oil, No. 4 Common Synonyms: Caswell No.14 333AB; Cat cracker feed stock; EINECS 270-673-5; EPA Pesticide Chemical Code 063514; Fuel oil No. 4; Diesel fuel No. 4.

- CASRNs: 8008-20-6 Primary Name: Kerosene Common Synonyms: JP-5 navy fuel/marine diesel fuel; Deodorized kerosene; JP5 Jet fuel; AF 100 (pesticide); Caswell No. 517; EINECS 232-366-4; EPA Pesticide Chemical Code 063501; Fuel oil No. 1; Fuels, kerosine; Shell 140; Shellsol 2046; Distillate fuel oils, light; Kerosene, straight run; Kerosine, (petroleum); Several Others.

Images: “Graphic” by Top Energy Training