One straightforward way of reducing CO2 emissions into the atmosphere is to capture CO2 at the point it is produced; this is called a point source. Point sources can be large or small, and mobile or stationary. Examples of mobile point sources include cars, ships, airplanes, construction vehicles—essentially, any vehicle that uses a carbon-emitting fuel to move. Stationary point sources include power plants, cement plants, gas refineries, and other types of industrial facilities that emit CO2 as a direct or indirect byproduct of production.1Kelemen, P., Benson, S. M., Pilorgé, H., Psarras, P., & Wilcox, J. (2019). An overview of the status and challenges of CO2 storage in minerals and geological formations. Frontiers in Climate, 1, 9.

Although in theory it is possible to capture CO2 at every single point source, there are millions of vehicles in motion all around the world, and millions more stationary sources, all emitting varying amounts of CO2 into the atmosphere. Carbon capture makes the most sense logistically and economically when it is applied to large, stationary point sources such as power plants and refineries. An International Energy Agency survey found that the top 13% of emission sources account for 85% of emissions.2IEA GHG. (2000). Greenhouse Gas Emissions from Major Industrial Sources III. So, if we want to efficiently and effectively capture CO2 at the source, large stationary point sources should be the main focus of any carbon capture project.

Utilization and Storage

So, what do we do with CO2 once it has been captured? CCUS implements two methods: utilization and storage. As we will discuss later, CO2 has value as a commodity in a number of different industries, and revenue from selling this commodity can help defray the costs of capture and transportation of the gas. However, current demand for CO2 is not significant enough to account for all of the gas we might target for capture. For the rest of the captured CO2, there is an elegant solution: put it back in the ground.

The technology is not new—the technology for injecting CO2 into existing oil and gas reservoirs has existed for decades, used as a method of enhanced oil recovery (EOR). Subsurface reservoirs exist—suitable reservoirs for storing CO2 include saline aquifers, depleted oil and gas reservoirs (some associated with EOR), possibly hydraulically fractured shale formations, and thick formations of igneous rocks (basalt and peridotite). We can use these same principles to inject CO2 into depleted reservoirs, or using the concept of “Stacked Storage”, we can leverage existing well infrastructure to inject CO2 into nearby saline aquifers that have similar gas-retention properties. Today two carbon capture projects are attached to power plants in North America: Petra Nova in Texas and the SaskPower Boundary Dam Power Station in Canada. The CO2 captured from both point sources is used in CO2-EOR projects.

Petra Nova in Texas

From initial start-up in December 2016 to the end of the three-year demonstration period, the Petra Nova facility captured 92.4% of CO2 from flue gas. NRG Energy and JX Nippon Oil partnered to retrofit one of the boilers at the WA Parish Generating Station in Texas with a post-combustion carbon capture treatment system. Captured CO2 was initially sent to Hilcorp’s EOR program in the West Ranch oil field southwest of Houston. Given the state of oil markets, in May 2020 the carbon capture facility was placed in reserve shutdown status to allow it to be brought back online when economic conditions improve.3NRG. (n.d.). Carbon capture and the future of coal power. Retrieved 01/04/2023 from https://www.nrg.com/case-studies/petra-nova.html

Boundary Dam Project in Canada

SaskPower’s Boundary Dam Integrated Carbon Capture and Storage Demonstration Project was initiated to capture CO2 from power generation and provide a low-cost source of CO2 to the mature Weyburn oil field for EOR. When the project began in 2014, it was the world’s first commercial-scale lignite-fired power plant equipped with carbon capture and storage technology.4Boundary Dam Power Station. (n.d.). In Wikipedia. Retrieved 11/3/2020 from https://en.wikipedia.org/wiki/Boundary_Dam_Power_Station

Aquistore was designed as Canada’s first dedicated CO2 storage project to provide buffer storage between capture and EOR operations. The storage project injects a portion of the CO2 captured by the Boundary Dam Project into the basal Cambrian formations of southern Saskatchewan. The larger percentage captured is sent to the nearby Weyburn oil field. Boundary Dam’s incorporation of Aquistore represents the first project in Canada to demonstrate a complete system for the capture, transportation, injection and storage of anthropogenic (human-derived) CO2 into a formation not associated with oil and gas recovery.5University of North Dakota Energy & Environmental Research Center. (n.d.). Aquistore Project. Retrieved 11/3/2020 from https://undeerc.org/pcor/co2sequestrationprojects/Aquistore.aspx

Direct Air Capture

While there has been significant progress in demonstrating CCUS using concentrated point sources (>10 volume% CO2) from coal fired power plants or ethanol fermenters, there is potential to capture, convert or otherwise manage carbon by using normal air. A new technology is making headlines: direct air capture (DAC).

Through DAC, a facility directly captures CO2 from the ambient air (.04 volume% CO2) and generates a concentrated stream of CO2. During the process, ambient air flows over a sorbent that selectively removes the CO2. Then the CO2 is released as a concentrated stream for storage or reuse, while the sorbent is regenerated and the CO2-depleted air is returned to the atmosphere.6American Physical Society. (2011, June 1). Direct air capture of CO2 with chemicals. Retrieved 11/3/2020 from https://www.aps.org/policy/reports/assessments/upload/dac2011.pdf

DAC technology is scalable and geographically flexible, offering broad potential as a negative-emissions technology. Currently, energy costs per ton of CO2 desorption are a major barrier facing DAC implementation. Nevertheless, research and commercial projects are moving forward. On September 1, 2020 the U.S. Department of Energy (DOE) awarded a total of $21 million to projects for DAC technologies. And a number of companies are partnering on DAC projects.7USDOE. (2020, September 1). Department of Energy invests $72 million in carbon capture technologies. Retrieved 11/3/2020 from https://www.energy.gov/articles/department-energy-invests-72-million-carbon-capture-technologies

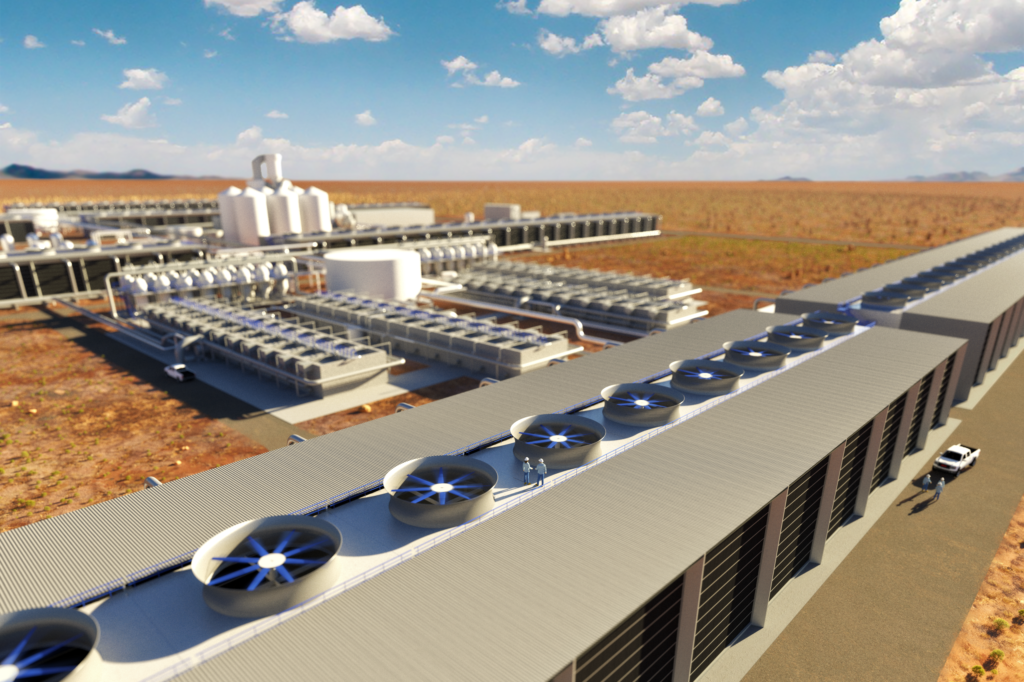

In 2019 Occidental became one of the first major oil companies to invest in developing DAC factories. The company invested in Carbon Engineering, a Canadian business that developed a DAC pilot plant outside of Vancouver. Together, the companies have begun the construction of the world’s largest DAC and sequestration facility, located in the Permian Basin with a land footprint of approximately 100 acres. The facility will initially capture 500,000 tons/yr of CO2, with an expansion planned to 1 million tons/yr.8Globe Newswire. (2020, August 19). Oxy Low Carbon Ventures, Rusheen Capital Management create development company 1PointFive to deploy Carbon Engineering’s Direct Air Capture technology. Retrieved 11/3/2020 from https://www.globenewswire.com/news-release/2020/08/19/2080502/0/en/Oxy-Low-Carbon-Ventures-Rusheen-Capital-Management-create-development-company-1PointFive-to-deploy-Carbon-Engineering-s-Direct-Air-Capture-technology.html9Blum, J. (2019, May 21). Oxy moves forward on Permian ‘direct air capture’ plant. Houston Chronicle. Retrieved 11/3/2020 from https://www.chron.com/business/energy/article/Oxy-moves-forward-on-Permian-direct-air-capture-13867251.php

When operational, the facility will be the largest DAC plant in the world, capturing up to one Mt of atmospheric CO2 annually. Currently, the world’s largest individual DAC facilities have the capacity to capture several thousand tonnes of CO2 per year. The CO2 captured (500,000 t/yr) at the facility will be stored by Occidental in the subsurface using two methods. First, Occidental will use the CO2 as part of their enhanced recovery program in the Permian. The company uses 50 Mt of CO2 annually for enhanced recovery, which permanently stores CO2 as part of the process. Second, geologic sequestration will deliver permanent CO2 removal. Occidental plans to use these two methods to help achieve their ultimate goal: to put more CO2 into the ground than it takes out in the form of fossil fuels. Partnerships on commercial development of DAC facilities has been made possible by market-based policies in the U.S., such as the California Low Carbon Fuel Standard and Federal 45Q tax credit.10Globe Newswire. (2020, August 19). Oxy Low Carbon Ventures, Rusheen Capital Management create development company 1PointFive to deploy Carbon Engineering’s Direct Air Capture technology. Retrieved 11/3/2020 from https://www.globenewswire.com/news-release/2020/08/19/2080502/0/en/Oxy-Low-Carbon-Ventures-Rusheen-Capital-Management-create-development-company-1PointFive-to-deploy-Carbon-Engineering-s-Direct-Air-Capture-technology.html11Blum, J. (2019, May 21). Oxy moves forward on Permian ‘direct air capture’ plant. Houston Chronicle. Retrieved 11/3/2020 from https://www.chron.com/business/energy/article/Oxy-moves-forward-on-Permian-direct-air-capture-13867251.php12Energy Intelligence. (2022, November 1). Oxy Leases Land for More DAC Plants. Retrieved 1/4/2023 from https://www.energyintel.com/00000184-3417-d911-a7ad-bd1fee4d0000

General Challenges to CCUS

CCUS has the potential to drastically reduce the amount of anthropogenic CO2 in the atmosphere. Known subsurface reservoirs are capable of storing large quantities of CO2. In 2013, the U.S. Geological Survey estimated a mean storage potential of 3,000 Gt of CO2.13USGS. (n.d.). How much carbon dioxide can the United States store via geologic sequestration? Retrieved 10/27/2020 from https://www.usgs.gov/faqs/how-much-carbon-dioxide-can-united-states-store-geologic-sequestration? For reference, the International Energy Agency reported global 2019 emissions at 33 Gt.14International Energy Agency. (2020). Global CO2 emissions in 2019. Retrieved 10/27/2020 from https://www.iea.org/articles/global-co2-emissions-in-2019 If implemented at a global scale, CCUS technology could significantly reduce the amount of CO2 in the atmosphere with the goal of reducing global climate change.

There are currently 29 operating facilities with a cumulative capture capacity of nearly 40 Mt per year. There are now over 100 facilities across all stages of development and across a range of sectors.15Global CCS Institute. (n.d.). CCS Explained: The Basics. Retrieved 1/4/2023 from https://www.globalccsinstitute.com/resources/ccs-101-the-basics/ Compare the ability to remove 40Mt per year with the emissions level of 33 Gt listed above. Why this disparity, if we have the technology, and we know where the reservoirs are? Simply put, storing CO2 costs money and doesn’t turn a profit. In addition to raise awareness about this widely available technology that could meet our climate goals, CCUS advocates are tasked with helping create regulatory, business, and social incentives for corporations and governments to adopt CCUS at the scale required to combat climate change. Lack of progress has more to do with politics and economics than with technology. But new regulatory and financial incentives, as well as more social acceptance, have led to CCUS becoming one of the most important next-generation low-greenhouse gas emissions technologies.

Images: “Fayette Power Project” by Courtesy Jeffrey M. Phillips