How CO2-EOR Works

Why is CO2 injection such an effective tactic for producing remaining OOIP when primary and secondary recovery techniques have peaked? Several physical mechanisms enhance oil production when CO2 is introduced into the reservoir.

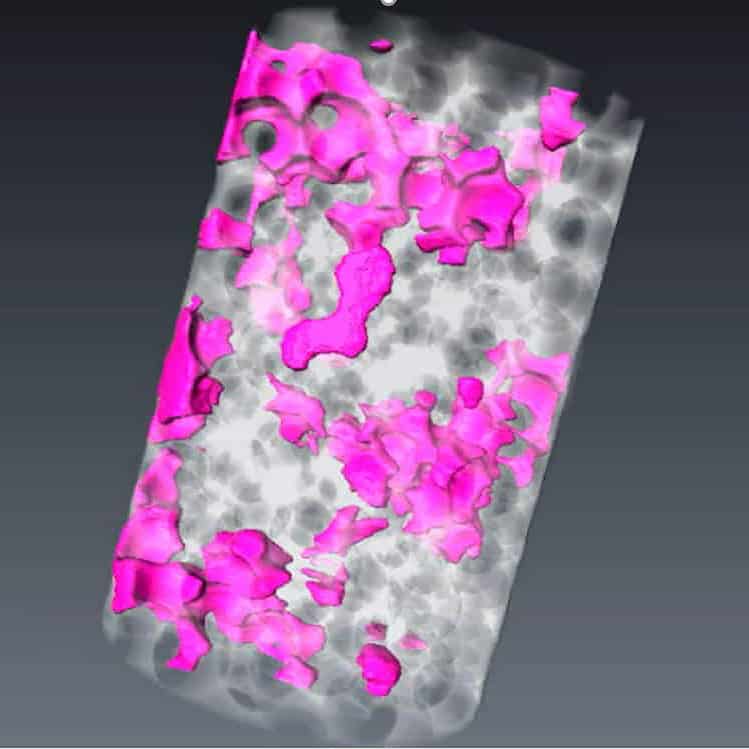

If the technology is applied after water flooding, the goal is to produce the mobile oil that was bypassed by water and the immobile residual oil trapped by capillary force. In the desirable case where the reservoir pressure is above the minimum miscibility pressure (MMP) and the injected CO2 and residual oil are miscible, the physical forces holding the two phases apart (interfacial tension) effectively disappear. This promotes a mass transfer of light and intermediate hydrocarbons, which reduces the residual immobile oil saturation. Additionally, the CO2-rich oil phase expands, regaining mobility. Mass transfer is improved at higher pressure, lower reservoir temperature and lighter oil. A reduction of mobile oil saturation can also be achieved through viscosity reduction, and pressure increase.

Because CO2-EOR is a displacement process, CO2 is injected into the deep subsurface rock reservoir through an injection well to displace oil toward a production well. CO2 is produced along with reservoir fluids, separated at the surface and, commonly, re-injected into the reservoir. The cycle repeats throughout the operation. For over 45 years, since the initial SACROC commercial development, the number of CO2-EOR projects has continued to grow steadily. This body of experience and success in the oil and gas industry has contributed to the development of CO2 handling, transportation and injection practices and technologies that are applicable to the development of CCUS regulations and the commercial development of CCUS projects.

Net Carbon Footprint of CO2-EOR

Even though large amounts of CO2 are geologically stored through EOR, the extent to which the technology can reduce greenhouse gas emissions remains an important question. We are able to address this through lifecycle analysis (LCA). LCA is a process that assesses the environmental impact that occurs throughout a product’s lifecycle, from raw materials acquisition through production, use, final treatment, recycling, and disposal.

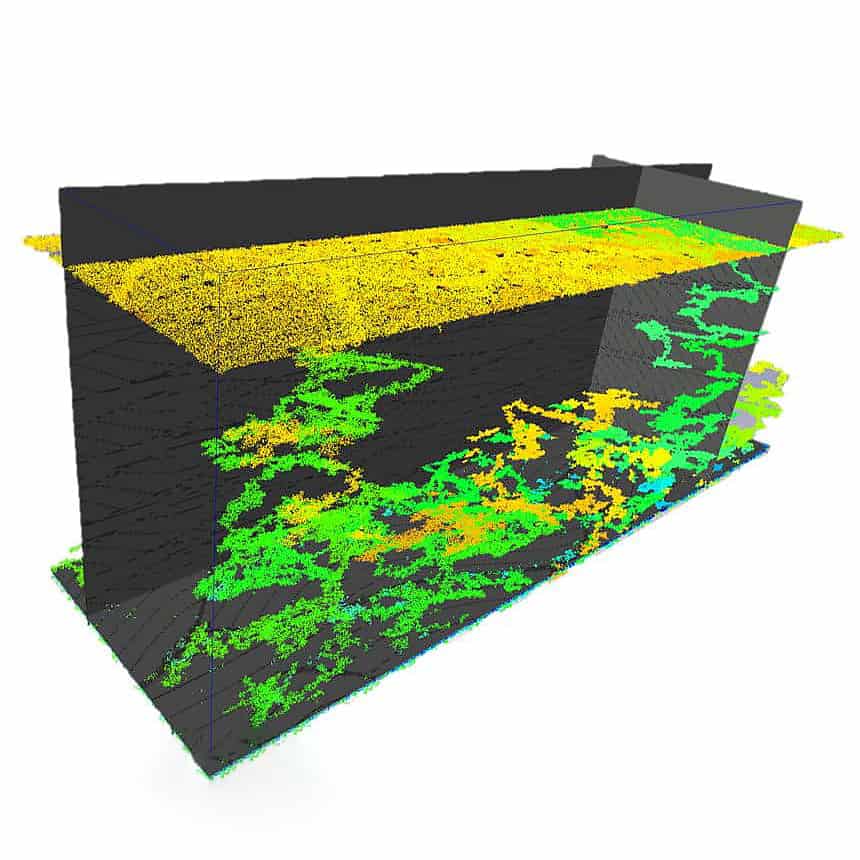

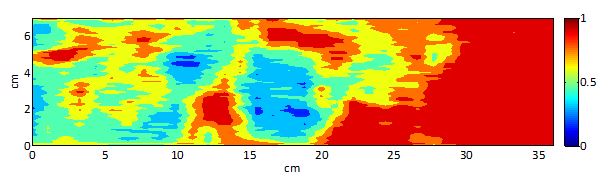

Important components of LCA applied to CCUS operations with EOR are the efficiency of the CO2-displacement process, which controls critical economic parameters such as oil production rate, CO2-utilization rate (mass of CO2 injected per barrel of oil produced), and CO2-recycle ratio. All these parameters are affected by reservoir rock characteristics, oil quality, production history, and other site-specific parameters. A first understanding of how all these variables play out in a specific setting is provided by reservoir modeling, a valuable tool used to visualize (among other things) the areal extent of the CO2 plume, as well as how the plume behaves within the subsurface. Results from reservoir modeling are used to delineate the extent of the area to which the CO2 plume will migrate and corrective action required in Class II injection operations.

LCA applied to CO2-EOR answers the question of whether CO2 emissions resulting from the EOR energy consumption and, more significantly, from the combustion of the incremental oil produced, are offset by the mass of anthropogenic CO2 stored. Recent studies at The University of Texas at Austin Bureau of Economic Geology on LCA for EOR conclude that the technology has potential for decarbonization during the first several years of operation.2Nuñez-López, V., & Moskal, E. (2019). Potential of CO2-EOR for Near-Term Decarbonization. Frontiers in Climate, 1, 5.