You’re going to be hearing a lot about cement jobs in this course. That’s because a well-done cement job is key to the safe and environmentally sound operation of a well. As you’ve seen, cement prevents fluid and gas from migrating up the outside of the casing. It also isolates the wellbore from surrounding formations, allowing pressure to be increased at depth without fracturing shallow rocks.

Functions of Cement

In summary, cement has several functions, including:

- support the casing

- retard casing corrosion

- protect freshwater zones

- isolate oil, gas, and water-bearing zones

- stabilize the borehole

Drillers should, and do, go to great lengths in order to ensure that a casing is cemented properly.

One particularly useful tool for this task is the cement bond logging tool, a sound-based wireline tool designed to assess the integrity of casing cement. In the following video, we’ll take a look at how this tool is used for this task.

Transcript

Cement Bond Logs – Azra N. Tutuncu – Colorado School of Mines

Since cementing the casing is such an important part of the drilling process, operators need to make sure that they’ve done a good job before they can begin drilling the next interval of the well.

If the well doesn’t meet regulatory standards, the cement job will need to be improved as well-bonded cement not only supports the casing, but also prevents fluids in the subsurface formations from leaking into an aquifer or to surface, and isolates producing zones from water-bearing zones.

To test the integrity of a cement job, operators use cement bond logging tools. These tools are lowered into the hole and provide a series of continuous measurements allowing operators to look at the quality and completeness of the cement bond.

Cement bond logging tools typically use acoustic wave propagation to examine the cement – but not directly as it is behind the casing.

These tools have a source that sends an acoustic signal into the casing wall, and then have a receiver to listen to the echoes. When the acoustic wave generated by the transmitter reaches the casing wall, part of it is refracted down the casing, part of it travels through the mud and the rest of the signal is refracted in the annulus and within the formation, received back and recorded.

Depending on how many echoes there are, how loud they are, and how quickly they die off, operators can see whether or not the cement job was executed properly and if there was a good bond created between the casing and the cement placed in the annulus between the casing and the wellbore.

Three key factors impacting the quality of the cement bond. These are; cement job design and execution including effective mud removal, compressive strength of the cement in place, and temperature and pressure changes applied to the casing after cementing.

There are two classes of cement bond logging tools – omnidirectional conventional tools, and radial tools. Omnidirectional tools emit and record acoustic signals from all directions within the wellbore, and their measurements represent an average of all these directions. In contrast, radial tools rotate while they are lowered, allowing them to produce a map of the acoustic response around the entire wellbore to detect any uncemented channels.

Let’s take a look at some of these logs.

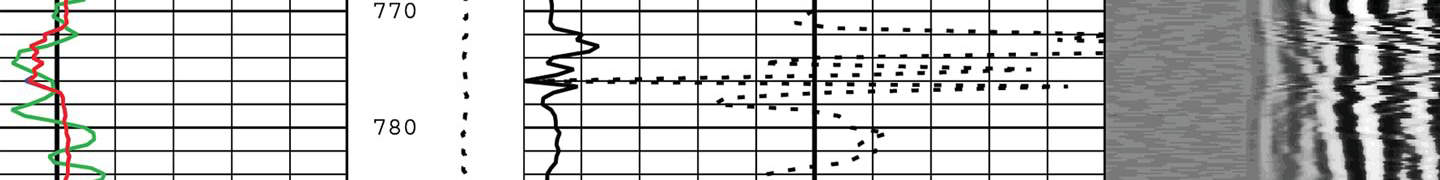

A typical cement bond log has three data columns. The first column shows a standard natural gamma ray log, which is included for operators to determine the location of the sensor within the stratigraphy more accurately.

The next column shows the amplitude of the sonic signal when it returns from the casing, cement and formation. The acoustic energy is rapidly lost in regions where cement bond quality is good and not in partial bonding or free pipe cases.

If the casing is well cemented, the signals are absorbed by cement and dispersed into the surrounding rock formations. By the time the signal reaches the sensor, it has lost most of its energy, and the amplitude is low.

If the casing is poorly cemented, the signal will be stronger, because not as much of the original energy is absorbed.

Think of it like hitting a bell with a hammer. If the bell is hanging freely, it will resonate, but if the bell has someone’s hands wrapped around it, the energy from the hammer is dispersed into the surrounding materials. The cement works like those hands to dull the signal response.

The third column contains a VDL, or “variable density log” which is an easy way to visualize changes in the acoustic property of the cement with depth.

Each sensor records the vibrations created by the source as a waveform, and there is a continuous-depth time display of the full-waveform amplitude presented as shades of black and white. Positive waveform amplitudes are shown as dark bands and negative amplitudes as gray or white bands. The contrast between them is proportional to the wave amplitude.

In an uncemented part of the well, all the stripes will appear as straight lines because the acoustic properties of the casing, which is reflecting all the signals, are constant. If the signals are making it through the cement and into the rock, the pattern will be curvier because different formations slow the waves down by different amounts.

It takes some experience to properly interpret all of the detailed information that a cement bond log presents, yet it’s something that regulators are often called upon to use, and it’s a critically important skill to insure the safe implementation of the oil and gas drilling, completion and production operations.

Images: “Cement Bond Log Illustration” by Top Energy Training