The largest sector of water withdrawal in the United States is thermoelectric power generation. In 2015, about 41% of all water withdrawals contributed to thermoelectric power generation.1USGS, 2019, Trends in Water Use, https://www.usgs.gov/mission-areas/water-resources/science/trends-water-use (accessed December 20, 2022). The primary function of all of this water is to cool large scale power plants.

Most of the water withdrawn for power plants is returned to the source, though at a different temperature and perhaps quality. The amount of water that is withdrawn and consumed by thermal power plants is driven by a mix of factors including the fuel, turbine design, cooling technology and local weather. Nuclear power plants require more water because, unlike power plants fueled by coal or natural gas, they cannot shed any waste heat into the atmosphere through smokestacks. The benefit of this scenario is that nuclear power plants lack emissions, but the disadvantage is that waterways absorb their waste heat.

The three most common power generation cooling methods are open-loop, closed-loop and air-cooling. On average, about 15 gallons (57 liters) of water are withdrawn and just under 1 gallon (4 liters) is consumed through evaporation for every kilowatt-hour (kWh) of electricity generated in the United States. Because typical U.S. homes use between 10 and 40 kWh of electricity each day, electric generation alone requires 300 to 600 gallons (1100 to 2300 liters) of cooling water per day.2Michael E. Webber, 2016, Resourcefulness: An Introduction to the Water-Energy Nexus (e-book)

Cooling Technologies

Open-loop (once-through) cooling withdraws large volumes of fresh or saline surface water, passes it through the power plant one time, and returns nearly all the water to the source with small quantities consumed along the way due to evaporation. While open-loop cooling is energy efficient and has low infrastructure and operational costs, discharged water is warmer than ambient water, causing thermal pollution, which can harm aquatic ecosystems. As a result, environmental agencies regulate discharge temperatures, taking into account a water body’s heat dissipation capacity. If power plant operators return water above the approved temperature limits, they may incur a fine or a curtailment order from the regulatory agency.

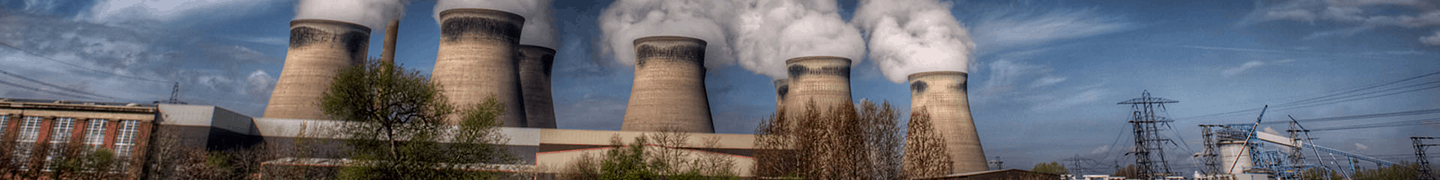

The stereotypical image of a closed-loop cooling tower is a concrete inverse parabola with white clouds of water vapor escaping to the atmosphere. Cooling towers withdraw water and then recirculate the water until it evaporates, which has a cooling effect. Because evaporation induces cooling, closed-loop cooling towers consume the water they take in.

Air cooling is the least water-intensive method of power plant cooling. With this technology, steam is diverted into tubes and fins. The heat transfer occurs between these tubes and the ambient air rather than a body of water. Some plants leverage the natural draft of air to transfer heat, and some plants use mechanical fans to drive air over the cooling range to improve the efficiency of heat transfer. You can think of air cooling as working very similar to the radiator in your car.

Images: “Power Station” by shipley43 licensed under CC BY 2.0