In order to come up with an effective production plan, operators need to know the character and quantity of hydrocarbons within the well.

Sources of Information

Most of the information needed to develop a production plan is collected during the exploration and formation evaluation phases of oil and gas recovery. As the well is approaching the production phase, petroleum engineers will use the information they’ve collected from earlier operations to characterize the reservoir and determine production requirements. Additional data may be obtained by studying wells already producing from the same reservoir.

Reservoir Characteristics

As we learned earlier, productive reservoirs contain hydrocarbons held in oil or gas trap. However, there are many other fluids and dissolved solids which can flow in a reservoir.

Non-hydrocarbon components, or contaminates in reservoirs can cause operational problems, as in the case of hydrogen sulfide, iron sulfides, or various carbonates.

Although producers need to know about all the fluids present in a reservoir, they’re ultimately most interested in the hydrocarbons.

One of the most important things operators need to know about a reservoir is what types of hydrocarbons it contains, and what form these hydrocarbons will take when they reach the surface.

Transcript

Reservoir Fluids – Matt Balhoff – The University of Texas at Austin

Reservoir fluids typically exist as three distinct phases in the void space of the subsurface rock: water, oil, and gas.

Water (actually salt water or “brine”) is present even in virgin reservoirs and accounts for approximately 15-25% of the fluid volume (which is saturation). This water is often referred to as connate water and initially is immobile (which is to say it does not flow). If secondary or tertiary recovery mechanisms are employed, water is injected into the reservoir and the water saturation can be much higher than 25% and will flow.

During secondary recovery, water will be produced, and in fact, eventually represents the majority of production fluids. At this point, the well is “watered out” and the reservoir is either abandoned or an enhanced oil recovery method is attempted.

Both the gas and oil phases are primarily petroleum (or hydrocarbons). The gas phase generally includes smaller molecules like Methane. Methane is often referred to as “natural gas” and is the simplest, smallest, and by far the most common hydrocarbon found in reservoirs. The gas phase may also include other small components (often used for heating) such as propane and butane.

The oil phase (what we call crude oil) is a really a melting pot of many different types of fluids mixed together, sometimes containing thousands of components, each made up of different types of molecules.

Some of these are small molecules like those found in the gas phase (like methane, propane, etc.) Some of the molecules are intermediates like pentane, heptane or octane.

These are often used in gasoline (think: octane rating at the gas pump). Other components of crude oil are very large, thick and dense – sometimes almost solid like. These fluids would be very difficult to flow by themselves.

In the reservoir, the gas, oil, and water phase separate and gas (the least dense phase) can be found mostly on top, oil mostly in the middle and water mostly on the bottom.

The fluids produced from the well at the surface will often include gas, oil and water. The oil phase at this point is sometimes called a “dead oil” because no more dissolved gas will be come out of the oil. The fluids are sent to a surface separator where the fluids are separated from their oil, gas and water phases and transported to refineries and disposal systems.

Hydrocarbons within a reservoir can take many forms. However, the form the hydrocarbons take at depth may be different from the form they take at surface conditions. Since the produced fluids are what ultimately will need to be processed, engineers need to know whether the well will produce liquids, gases, solids, or a combination of the three. This information allows operators to formulate a production system which will be prepared to process the materials produced at the surface.

To help operators categorize reservoirs by the types of hydrocarbons produced, reservoir engineers have come up with a reservoir classification system.

Reservoir Drive Mechanics

Reservoir drive refers to the combination of forces which cause reservoir fluids to enter the borehole. Maintaining reservoir drive is one of the key challenges faced by reservoir engineers during the early stages of production.

In addition to knowing the blend of hydrocarbons which a well will produce, operators need to know how the rate of production will change over time. This information allows operators to optimize their production plan in order to maximize the total economic oil and gas production. The most important predictor of future declines in production is the type of reservoir drive operating within the reservoir.

Typically, 10-20% of the hydrocarbons in a reservoir can be extracted with the help of reservoir drive during primary production. After primary production slows to uneconomical rates, more expensive recovery techniques are employed. Reservoir engineers try to get as much oil out of the ground using naturally occurring reservoir pressure drives as possible before employingmore costly methods.

Each type of reservoir drive creates a pressure gradient, which encourages oil and gas to flow towards the borehole. By studying geologic conditions in a specific reservoir, a reservoir engineer can predict which type of drive will dominate production.

Each type of drive is associated with a unique production decline curve. The curves describe how the rate of primary production will change as the energy provided by a drive mechanism is depleted.

Although idealized curves exist for each type of reservoir drive, most primary production is driven by a combination of two or more drive mechanisms. As a result, the real production curves are usually some combination of more than one idealized curve.

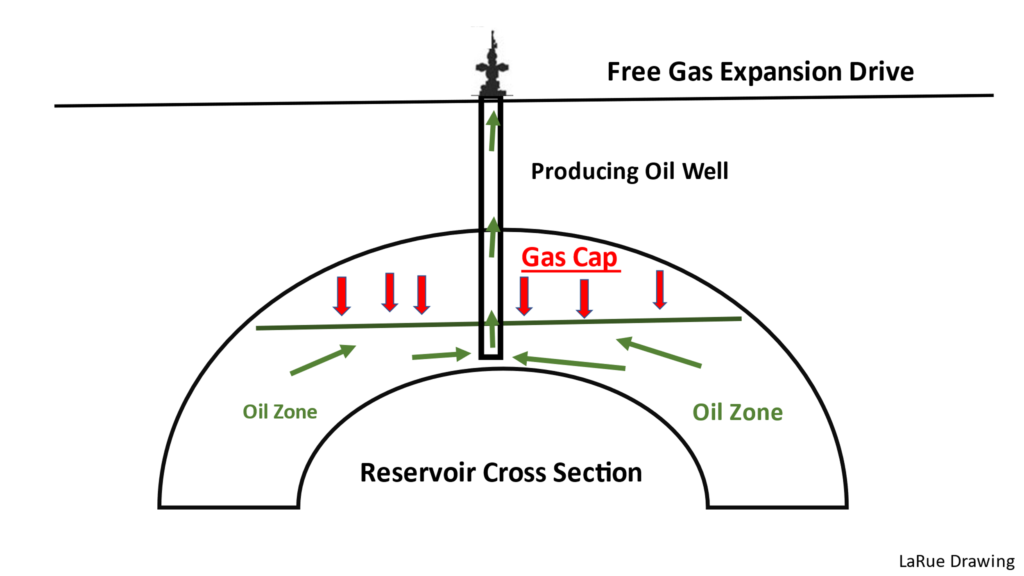

Free Gas Expansion

Free gas expansion occurs when a cap of gas is present above the oil in a structural trap. As oil is removed from below, the gas expands, exerting pressure on the oil and keeping it flowing into the borehole.

When producing from a formation where free gas expansion is occurring, oil production will remain high until the removal of oil allows the gas cap to expand downward to the bottom of the well. When this occurs, oil production drops off rapidly.

Reservoir engineers take great care to make sure that a gas cap is not extracted before it has been allowed to expand and drive the most oil to the surface.

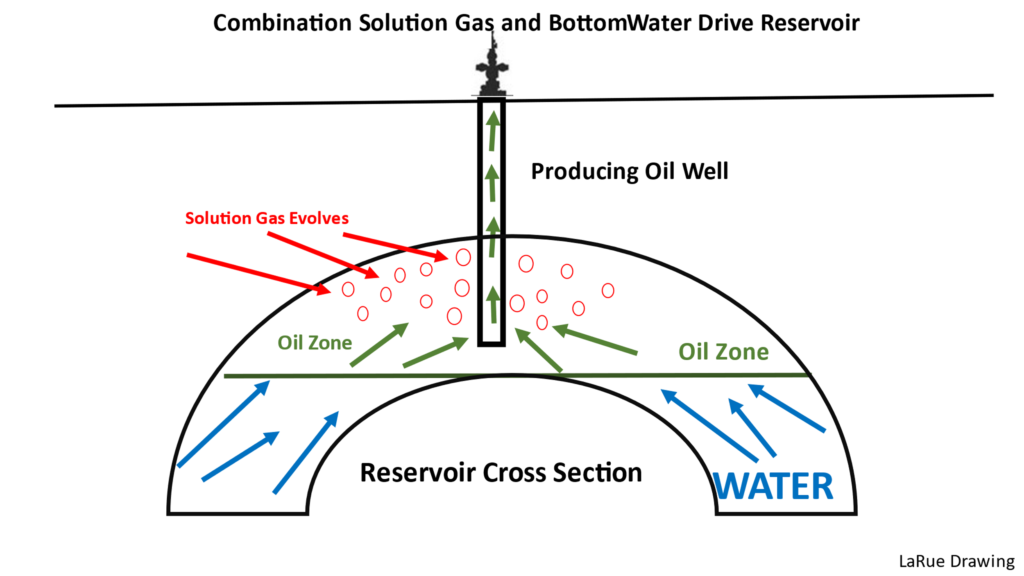

Dissolved Gas Expansion or Solution Drive

Within some oil reservoirs, natural gas is dissolved within the oil. As oil is removed from the reservoir, the pressure acting on the oil begins to drop, causing the gas to come out of solution. A similar process occurs when a bottle of soda is opened.

As the gas comes out of solution, it expands, increasing pressure on the oil in the reservoir and causes oil to flow to the borehole.

Water Drive

As oil is removed from a reservoir, brine sitting beneath the oil begins to expand. Water is slightly compressible, and the expansion of water is enough to cause some oil movement to occur. In addition, water rises to replace the oil and gas which was removed from the well, preventing a complete loss of pressure.

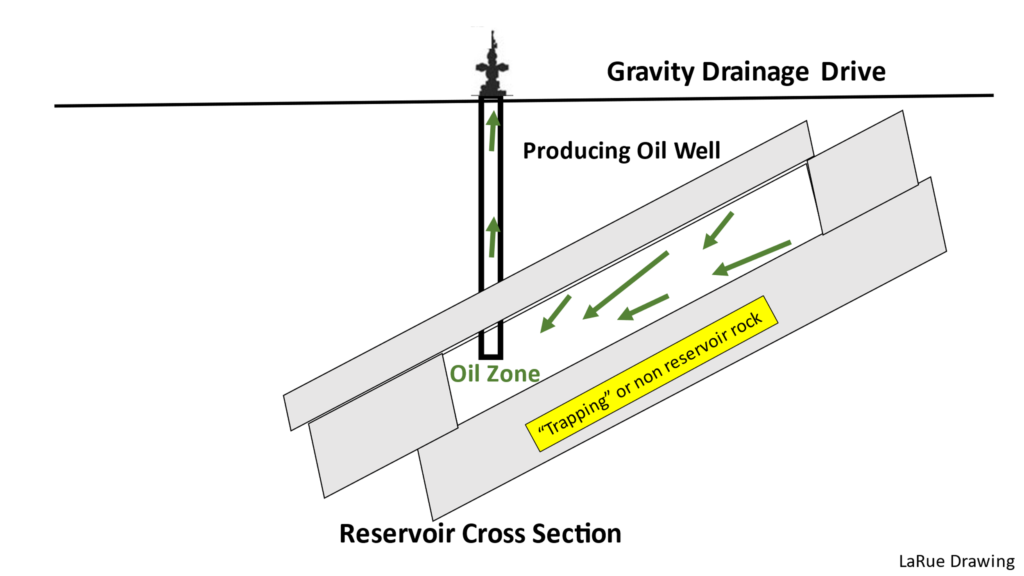

Gravity Drive

Once pressure-driven migration of oil due to gas and water expansion subsides, oil migration is dominated by gravity.

Gravity drive is much slower than the other types of drive.

Images: “Initial Exploratory Location” by Jim Blecha; “Illustration” by Top Energy Training; “Free-gas-expansion-LaRue” by Jon LaRue; “Combination-Solution” by Jon LaRue; “Gravity-Drainage-Drive” by Jon LaRue